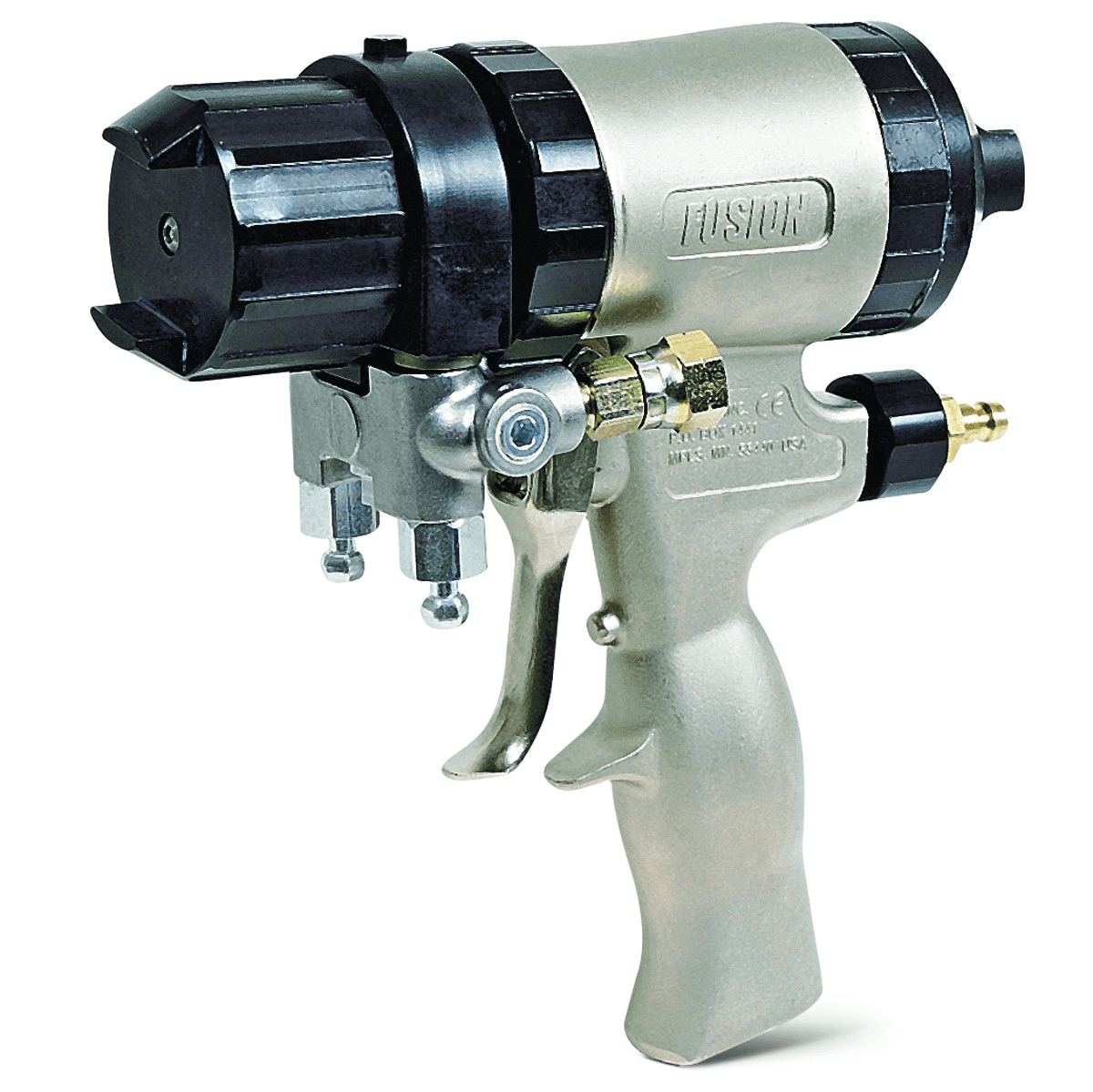

Here are two very quick and simple tips for keeping your Graco® Fusion gun in tip-top shape. If you haven’t already, be sure to add these into your routine. These simple maintenance tips will not only increase the life of your gun and equipment, but can prevent bed liner blistering and other installation issues.

Two Quick Tips

1. Check Gun for Leaks

With the valves below the gun turned off, pressure up your machine. Then, with the air to the gun on, crack the resin valve and look for a mist of air and resin. If there is mist and you are not getting just clean air, stop and close the valve. You have an internal leak in your gun. Bleed off pressure on the machine and fix your gun.

If all looks good on the resin side repeat this process on the ISO side. Again, if any ISO is coming out in the airstream STOP. You have an internal leak on the ISO side inside your gun, which needs to be fixed.

Ignoring this mist can lead to locked up guns and potentially blistered bed liners if the mist lands on the liner during application.

Other signs that point to a leak is if the grease in the gun becomes hard and crusty or if you find yourself frequently having to rebuild your gun, especially after a long weekend.

2. Seal Gun Nozzle from Humidity

After giving your gun a little shot of gun grease upon shutdown, smear some grease over the gun nozzle to seal it from air. This stops humid air from entering the gun through the nozzle and reacting with the ISO.

Need More Technical Tips?

Feel free to reach out to the Rhino Linings technical support team with any questions about your spray gun or other equipment. Or, if you’d like to see a specific topic addressed in a future technical article, email rhinomarketing@rhinolinings.com.

Leave A Comment