Drop-in bedliners are generally cheaper than spray-on bedliners. While they offer a quick and straightforward installation process, they offer very little in the way of safeguarding your vehicle. Going the cheaper route may not be the best option if you are looking to...

Our Blog

Removable Drum Head Procedures

Step 1 – Place the new Resin drum into position on the B-side of the machine (blue label side). Once the Resin drum is in place, remove the bolt by using a 13mm socket and an impact gun Slide the collar down the drum Remove the lid Step 2 – Using a ½” drill with the...

Cold Weather Storage and Foam Spraying Tips

Having a quality infrared thermometer and moisture meter to check barrel and substrate temperatures is a great way to stay ahead of the cold this winter. Self-adhesive LCD thermometers on the drums are also great as a quick reference. Do your best to avoid...

RhinoPure Hand Sanitizer 75% Off

Get Rhino Tough on Germs! Hand Sanitizer – Manufactured in America, RhinoPure Kills up to 99.99% of Germs. Up To $75% Off, Regular Retail Price of $35.99 for Liquid, $37.99 for Gel. For Orders: orders@rhinolinings.com https://rhinopure-hand-sanitizer.rhinolinings.com/

What Success Looks Like…. Rhino Lined

Edon Moyal, Vice President of Rhino Truck Accessory Center (RTAC), better known as Rhino Linings of San Diego, has made huge strides in the past few years to enhance a business that was already well established as the very first Rhino Linings location. Started by his...

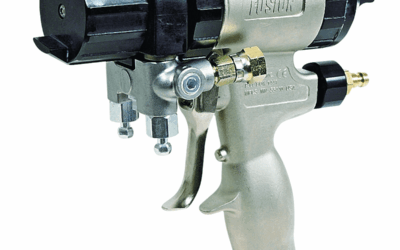

Monitoring Desiccant Beads and Cartridges

Desiccant beads are essential to the absorption of water vapor in your air system. They help prevent contaminants from entering your airline and polluting output. It is important to monitor desiccant beads often. A good way to determine when replacement is necessary...

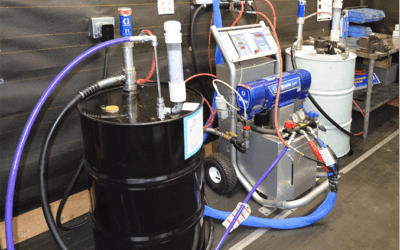

Two Quick Fusion Gun Maintenance Tips

Here are two very quick and simple tips for keeping your Graco® Fusion gun in tip-top shape. If you haven't already, be sure to add these into your routine. These simple maintenance tips will not only increase the life of your gun and equipment, but can prevent bed...

12 Best Tips for Spraying Top Notch Rhino Liners

How do you guarantee customer satisfaction? By putting out the very best Rhino Linings® bed liners. Below are 12 tips that help top Rhino Linings applicators apply the highest quality bed liners in the business. 1. Store Your Chemicals Well Keep chemicals stored at...

It May Be a Grind, but the Payoff Is Worth It

In order to obtain a permanent bond of the Rhino Linings® spray-on liner to the pickup truck bed, bumpers, fenders, or body panels, it is necessary to sand or scuff the paint finish within masked boundaries. An efficient and thorough prep job is vital in order to...

Are You Ready for Winter’s Impact on Your Operations?

Last year’s extreme winter conditions caused significant disruptions for many businesses. Due to extremely cold temperatures and poor road conditions or closures, many of you experienced delivery delays and received isocyanate that was cloudy or frozen. Avoid the...